Panasonic FT-A32 Wide Beam Fiber: Advanced Sensing for Industrial Automation

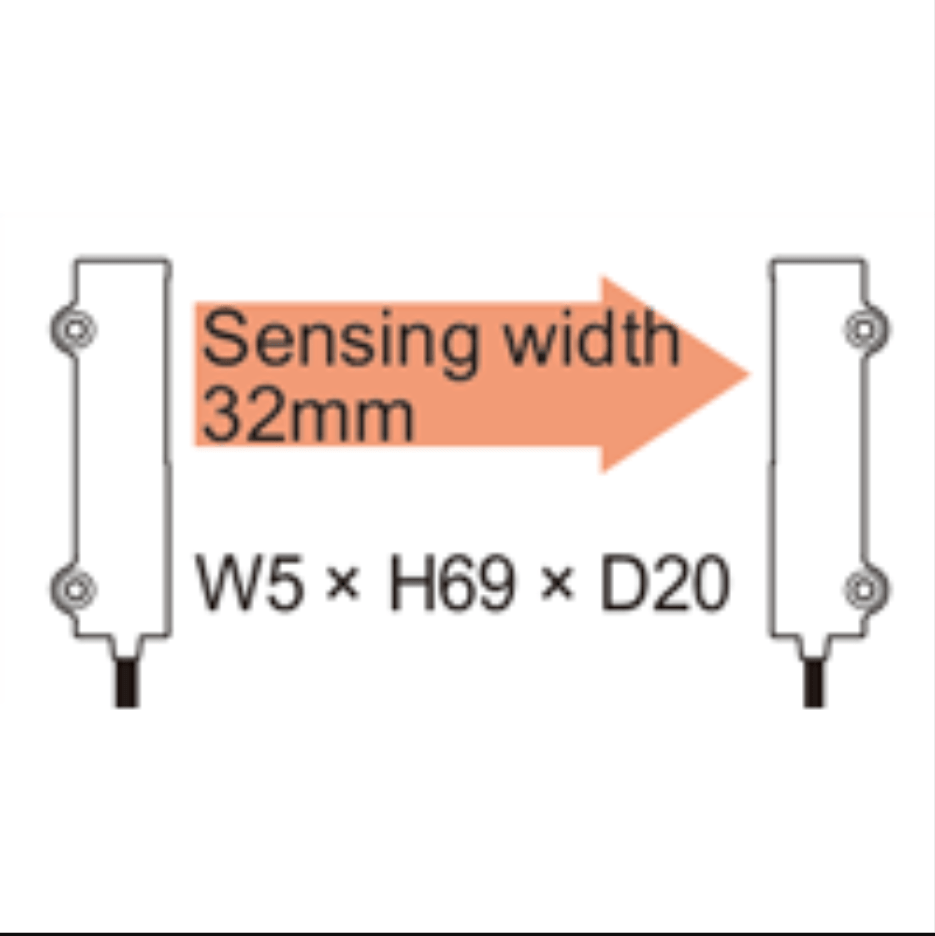

The Panasonic FT-A32 wide beam fiber is a high-performance thrubeam sensor designed for industrial automation. Featuring a 32mm wide beam array, 2m cuttable fiber cable, R2 bend radius, and IP40 protection, the Panasonic FT-A32 wide beam fiber excels in shape discrimination and general-purpose applications like conveyor system sensing and material handling detection. Its robust FT-A32 industrial fiber sensor capabilities, including object detection and industrial network compatibility, make it an ideal choice for automation sensor solutions. With easy installation and reliable performance, the Panasonic FT-A32 wide beam fiber enhances efficiency across diverse industrial settings.

Technical Specifications of Panasonic FT-A32 Wide Beam Fiber

The Panasonic FT-A32 offers a versatile design tailored for broad industrial needs. Below is a table of its key technical specifications:

| Parameter | Specification |

|---|---|

| Fiber Type | Thrubeam, 32mm wide beam array |

| Cable Length | 2m, cuttable |

| Bend Radius | R2 (2 mm) |

| Protection Rating | IP40 |

| Sensing Distance | Up to 3600 mm with FX-500 series (HYPER mode) |

| Compatibility | FX-500, FX-550, FX-100 series amplifiers |

| Standards | RoHS compliant (2011/65/EU, 2015/863/EU) |

Industrial Applications and Key Features

Shape Discrimination and Wide Area Sensing

The FT-A32 thrubeam fiber sensor is optimized for shape discrimination, making it ideal for industries such as packaging, electronics, and food processing. Its 32mm wide beam array ensures reliable detection of workpieces with irregular shapes or positions, enhancing the FT-A32 object detection sensor’s versatility. The FT-A32 high-precision fiber sensor delivers consistent performance in FT-A32 wide area sensing applications, improving operational accuracy and productivity.

General-Purpose Detection and Factory Automation

As a FT-A32 general-purpose fiber sensor, it excels in conveyor system sensing and material handling detection. The FT-A32’s IP40 protection supports reliable operation in controlled environments, while its R2 bend radius fiber provides flexibility for complex installations. Designed for FT-A32 factory automation fiber applications, this sensor ensures dependable performance in automated production lines, streamlining manufacturing processes.

Industrial Network Compatibility and System Integration

Compatible with Panasonic’s FX-500, FX-550, and FX-100 series amplifiers, the FT-A32 ensures seamless FT-A32 industrial network compatibility. Its optical communication function enables rapid configuration of multiple amplifiers, reducing setup time. The FT-A32 fiber optic datasheet and FT-A32 fiber optic installation guide, available through Panasonic’s official resources, provide detailed instructions for efficient integration, optimizing automation workflows.

Installation and Maintenance

The FT-A32’s 2m cuttable fiber cable and R2 bend radius simplify installation, accommodating diverse setups. The IP40 fiber sensor operates reliably in controlled environments, and the FT-A32 fiber optic installation guide offers clear, step-by-step instructions. Routine maintenance, such as cleaning fiber ends, ensures the longevity of this FT-A32 industrial fiber sensor, maintaining consistent performance over time.

Safety and Compliance

The FT-A32 is RoHS compliant (2011/65/EU, 2015/863/EU), reflecting its eco-friendly design. Operating stably between -40°C and +60°C, it meets industrial requirements. While its IP40 rating suits less harsh environments compared to IP67 sensors, the FT-A32 remains a reliable choice for FT-A32 automation sensor solutions.

Why Choose Panasonic FT-A32 Wide Beam Fiber?

The Panasonic FT-A32 fiber optic sensor is a versatile solution for industrial automation. Its 32mm wide beam array, 2m cuttable cable, and R2 bend radius offer flexible installation. Excelling in shape discrimination, object detection, and conveyor system sensing, the FT-A32 enhances productivity in material handling and automation tasks. The FT-A32 fiber optic datasheet and installation guide streamline integration, ensuring operational success. Choose the FT-A32 to advance automation, achieve reliable detection, and drive efficiency in your industrial operations.

Visit our blog about The Importance of Sensors in Industry 4.0.

Enhancing Detection Accuracy in Modern Automation Systems

The Panasonic FT-A32 wide beam fiber brings precision and reliability to complex automation environments where accuracy is critical. Its 32mm wide beam allows for uniform detection of large or irregularly shaped objects, minimizing false readings and improving the overall stability of production systems. This capability is particularly beneficial in automated packaging, electronics manufacturing, and assembly processes, where precision alignment and real-time monitoring are key to maintaining quality.

The FT-A32’s compatibility with advanced Panasonic amplifier series enables rapid signal processing and smart adjustment capabilities, making it adaptable to dynamic industrial operations. Whether integrated into a conveyor line or part of a multi-sensor network, the FT-A32 ensures consistent performance with minimal maintenance needs. Its efficient light distribution system also helps maintain accuracy over long sensing distances, even in complex setups.

Future-Ready Fiber Optic Sensing Technology

As industries embrace digital transformation, the Panasonic FT-A32 wide beam fiber stands out as a future-ready sensing solution. Its combination of durability, flexibility, and wide-area coverage aligns perfectly with Industry 4.0 requirements for intelligent automation and data-driven manufacturing. With its easy setup and reliable operation, the FT-A32 empowers engineers to build smarter, more responsive production environments.

Built for longevity and adaptability, the Panasonic FT-A32 wide beam fiber offers a balance of cutting-edge technology and practical functionality. It ensures optimal detection performance across diverse industrial sectors, helping businesses enhance efficiency, reduce downtime, and maintain consistent product quality in their automated systems.