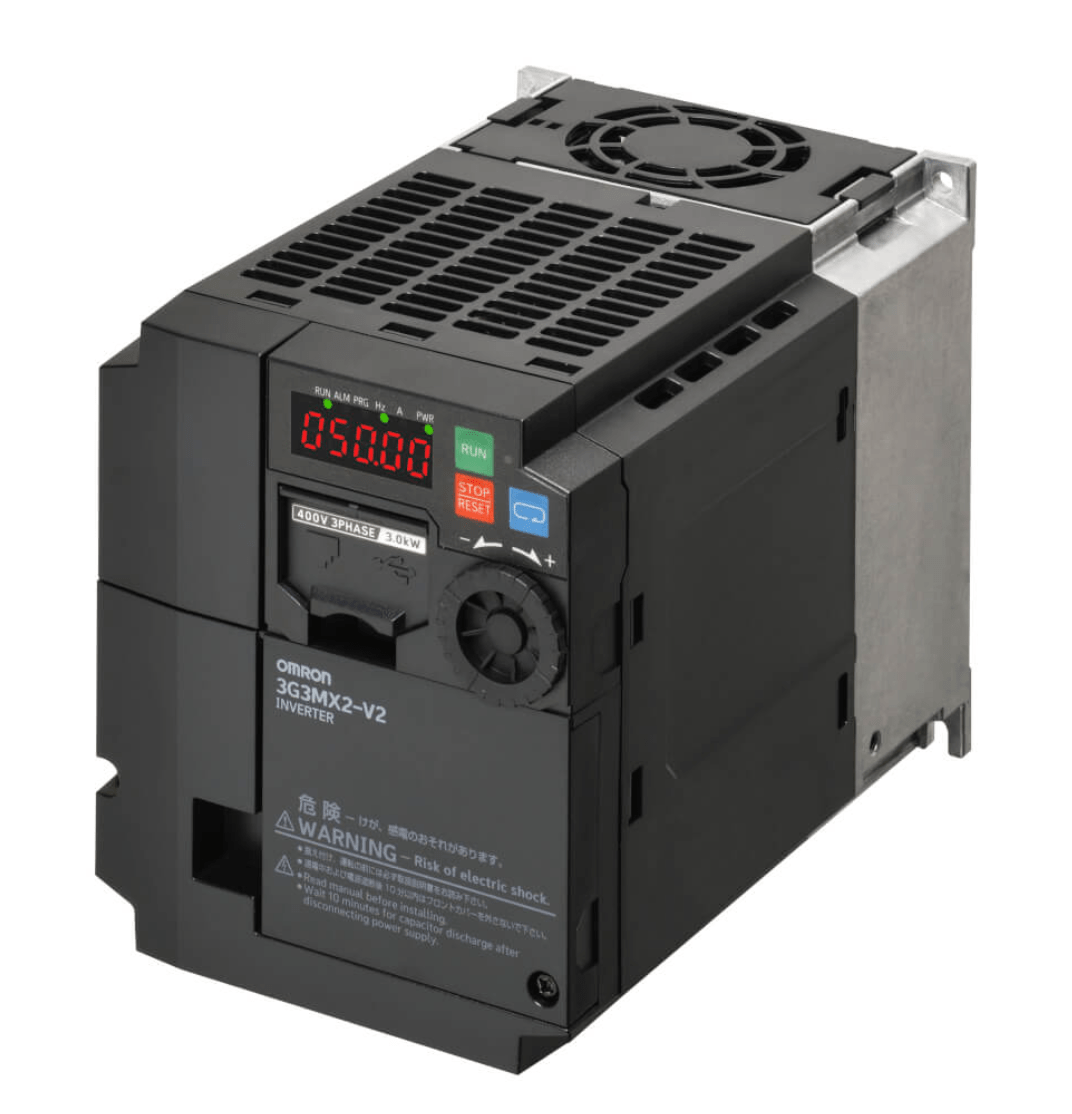

Elevate Automation with the Omron 3G3MX2-A4015-HF Inverter

The compact 3G3MX2-A4015-HF AC drive, part of Omron’s MX2 Series, delivers advanced motor control and high efficiency. This article explores the Omron 3G3MX2-A4015-HF inverter technical specifications and 3G3MX2-A4015-HF industrial applications, highlighting its critical role in factory automation.

Omron 3G3MX2-A4015-HF Inverter Technical Specifications

The high-efficiency 3G3MX2-A4015-HF inverter combines a compact design with robust performance. Key technical specifications are summarized in the table below.

| Feature | Details |

|---|---|

| Power Capacity | 1.5/2.2 kW (HD/ND) |

| Input Voltage | 3-phase 380-480 VAC |

| Output Current | 4.8/5.4 A (HD/ND) |

| Control Method | Sensorless vector control |

| Communication | Modbus-RTU, optional EtherCAT |

| Max. Output Frequency | 1000 Hz |

The 3G3MX2-A4015-HF motor control provides 200% torque at 0.5 Hz, enabling precise 3G3MX2-A4015-HF torque control and 3G3MX2-A4015-HF high-frequency control for high-speed applications.

Durability and Energy Efficiency

The reliable 3G3MX2-A4015-HF drive system, with IP20 protection, ensures consistent performance in harsh industrial environments. The energy-saving 3G3MX2-A4015-HF inverter reduces power consumption, lowering operational costs. The durable 3G3MX2-A4015-HF industrial inverter requires minimal upkeep, supported by streamlined 3G3MX2-A4015-HF maintenance procedures.

Industrial Applications and Connectivity

Tailored for 3G3MX2-A4015-HF factory automation, this inverter excels in 3G3MX2-A4015-HF conveyor systems, pumps, fans, and high-speed machinery. The 3G3MX2-A4015-HF Modbus communication and optional EtherCAT enable robust 3G3MX2-A4015-HF industrial network connectivity. The 3G3MX2-A4015-HF system integration ensures seamless compatibility with PLCs, optimizing automation workflows.

Easy Installation and Technical Support

The 3G3MX2-A4015-HF installation requirements are designed for quick setup. The 3G3MX2-A4015-HF programming guide, compatible with CX-Drive software, simplifies configuration. The 3G3MX2-A4015-HF troubleshooting guide minimizes downtime, and the 3G3MX2-A4015-HF technical datasheet is available from trusted suppliers.

Why Choose the Omron 3G3MX2-A4015-HF Inverter?

The 3G3MX2-A4015-HF inverter combines energy efficiency, durability, and advanced 3G3MX2-A4015-HF sensorless vector control. Its high-frequency capability and versatile communication options make it ideal for modern automation needs. With 3G3MX2-A4015-HF system integration, your facility achieves maximum efficiency.

Contact Trusted Suppliers

Reach out to reliable suppliers for competitive pricing and expert support. Request the 3G3MX2-A4015-HF technical datasheet to explore its features in detail. Elevate your operations with the 3G3MX2-A4015-HF inverter and drive productivity forward.

You can also visit our Omron Sensors page!

Enhanced Motor Precision and System Adaptability

The Omron 3G3MX2-A4015-HF inverter delivers superior motion control designed to support complex and high-speed industrial processes. Its advanced sensorless vector control ensures stable torque even at extremely low speeds, enabling smooth acceleration and deceleration without compromising accuracy. This makes the inverter especially suitable for demanding applications such as precision conveyors, high-speed cutting machinery, and dynamic material handling systems. Its extended frequency range further enhances responsiveness, allowing production lines to achieve consistent and repeatable results.

Engineers benefit from a wide array of adjustable parameters, enabling seamless adaptation to diverse automation requirements. The built-in logic functions support customized operational scenarios without the need for extra control hardware, simplifying system architecture and reducing installation time. With its compact footprint and optimized wiring layout, the 3G3MX2-A4015-HF integrates efficiently into both new installations and retrofit projects where space and flexibility are crucial. This adaptability helps facilities maintain smooth production flow and achieve long-term operational stability.

Real-Time Monitoring and Reliable Performance

The inverter’s real-time monitoring tools give operators essential insights into motor load, energy consumption, operating temperature, and frequency behavior. Such detailed data helps optimize performance, reduce unnecessary energy usage, and enable predictive maintenance strategies that minimize downtime. Equipped with robust protection features—including safeguards against overload, overheating, and voltage fluctuations—the 3G3MX2-A4015-HF ensures safe and uninterrupted operation even in demanding environments. Combined with its high-frequency capabilities and intelligent control structure, this inverter provides a dependable and efficient foundation for elevating modern automation systems.