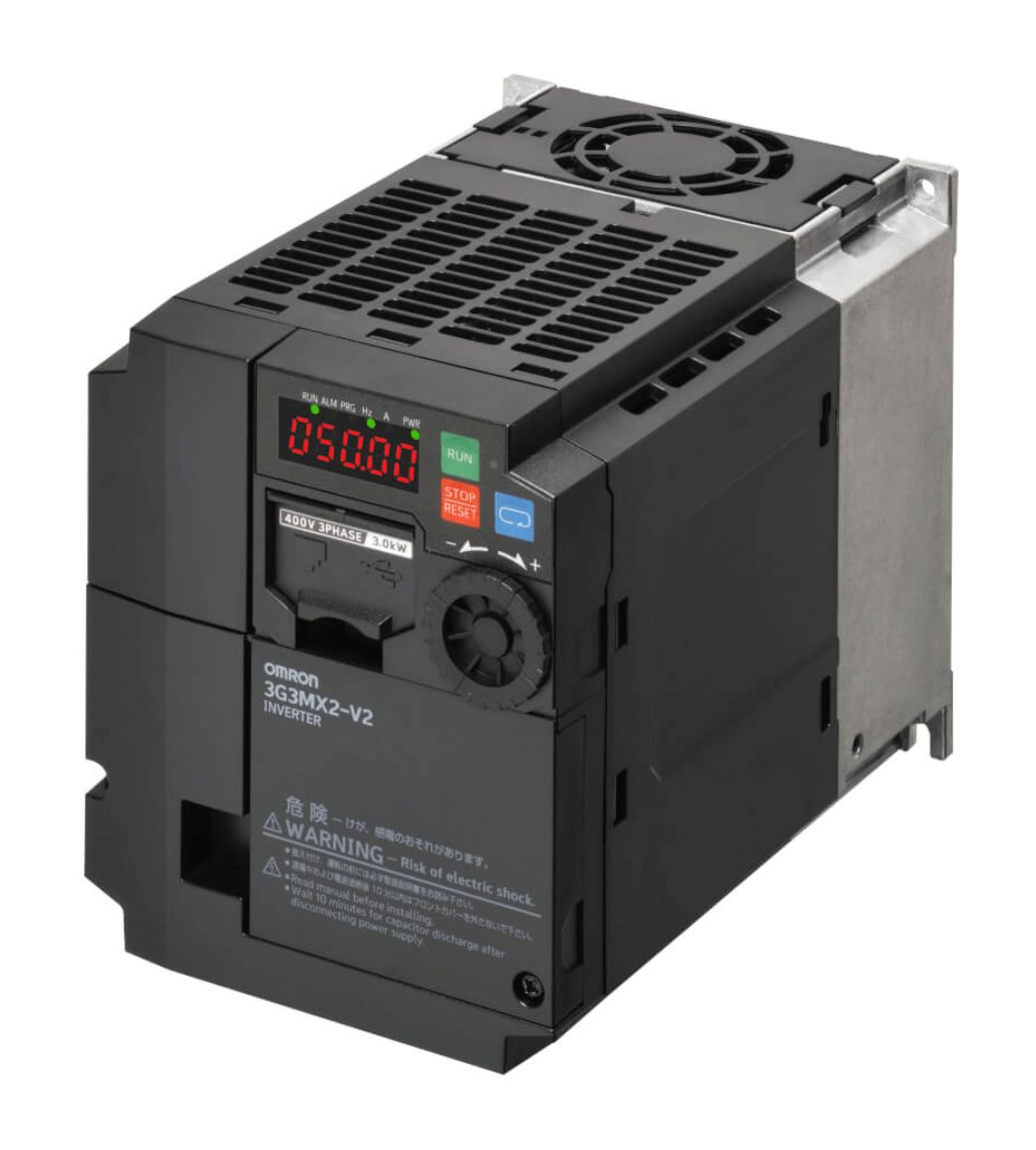

Enhance Automation with the Omron 3G3MX2-A4004-EV2 Inverter

The compact 3G3MX2-A4004-EV2 AC drive, part of Omron’s MX2-EV2 Series, delivers advanced motor control and efficiency. This article explores the 3G3MX2-A4004-EV2 inverter technical specifications and 3G3MX2-A4004-EV2 industrial applications, highlighting its critical role in factory automation.

Omron 3G3MX2-A4004-EV2 Inverter Technical Specifications

The high-efficiency Omron 3G3MX2-A4004-EV2 inverter offers robust performance in a compact design. Key technical specifications are outlined below.

| Feature | Details |

|---|---|

| Power Capacity | 0.4/0.75 kW (HD/ND) |

| Input Voltage | 3-phase 380-480 VAC |

| Output Current | 1.8/2.1 A (HD/ND) |

| Control Method | Sensorless vector control |

| Communication | Modbus-RTU, optional EtherCAT |

| Max. Output Frequency | 590 Hz |

The 3G3MX2-A4004-EV2 motor control delivers 200% torque at 0.5 Hz, ensuring precise 3G3MX2-A4004-EV2 torque control for demanding applications.

Durability and Energy Efficiency

The reliable 3G3MX2-A4004-EV2 drive system, with IP20 protection, performs consistently in industrial environments. The energy-saving 3G3MX2-A4004-EV2 inverter reduces power consumption, lowering operational costs. The durable 3G3MX2-A4004-EV2 industrial inverter requires minimal maintenance, supported by 3G3MX2-A4004-EV2 maintenance procedures.

Industrial Applications and Connectivity

Designed for 3G3MX2-A4004-EV2 factory automation, this inverter excels in 3G3MX2-A4004-EV2 conveyor systems, pumps, fans, and mixers. The 3G3MX2-A4004-EV2 Modbus communication and optional EtherCAT provide robust 3G3MX2-A4004-EV2 industrial network connectivity. The 3G3MX2-A4004-EV2 system integration enhances compatibility with PLCs, streamlining automation processes.

Easy Installation and Support

The 3G3MX2-A4004-EV2 installation requirements are optimized for quick setup. The 3G3MX2-A4004-EV2 programming guide, compatible with CX-Drive software, simplifies configuration. The 3G3MX2-A4004-EV2 troubleshooting guide minimizes downtime, and the 3G3MX2-A4004-EV2 technical datasheet is available from trusted suppliers.

Why Choose the Omron 3G3MX2-A4004-EV2 Inverter?

The Omron 3G3MX2-A4004-EV2 inverter combines energy efficiency, durability, and advanced 3G3MX2-A4004-EV2 sensorless vector control. Its compact design and versatile communication options make it ideal for modern automation. With 3G3MX2-A4004-EV2 system integration, your facility achieves maximum efficiency.

Contact Trusted Suppliers

Connect with reliable suppliers for competitive pricing and expert support. Request the 3G3MX2-A4004-EV2 technical datasheet to explore its features. Transform your operations with the 3G3MX2-A4004-EV2 inverter and elevate efficiency.

You can also visit our Omron Sensors page!

Advanced Motion Control and Application Adaptability

The Omron 3G3MX2-A4004-EV2 inverter enhances automation performance with its refined control algorithms and fast response characteristics. Its sensorless vector control ensures smooth torque delivery across a wide speed range, making it an ideal choice for equipment requiring stable low-speed precision. Applications such as feeders, synchronized conveyors, and precision mixing systems greatly benefit from this level of control. The inverter’s ability to handle sudden load variations without compromising performance contributes to improved operational stability and extended equipment life.

Beyond its strong core performance, the 3G3MX2-A4004-EV2 inverter offers flexible programmability designed to simplify customization in industrial environments. Integrated logical functions allow engineers to create application-specific behaviors without additional controllers, reducing installation complexity and total system cost. This flexibility ensures seamless integration into both newly designed systems and retrofit projects, offering consistent reliability across different automation scenarios.

Operational Insight and Process Improvement

The 3G3MX2-A4004-EV2 includes comprehensive monitoring tools that allow operators to evaluate system performance in real time. By tracking energy consumption, motor load, and operational patterns, facilities can optimize processes and identify inefficiencies early. These insights support proactive maintenance strategies and help prevent unexpected downtime. The inverter’s extensive protective functions—covering overload, overvoltage, and thermal conditions—further ensure safe and reliable operation. With these capabilities, the 3G3MX2-A4004-EV2 contributes to sustainable, efficient, and data-driven automation performance.