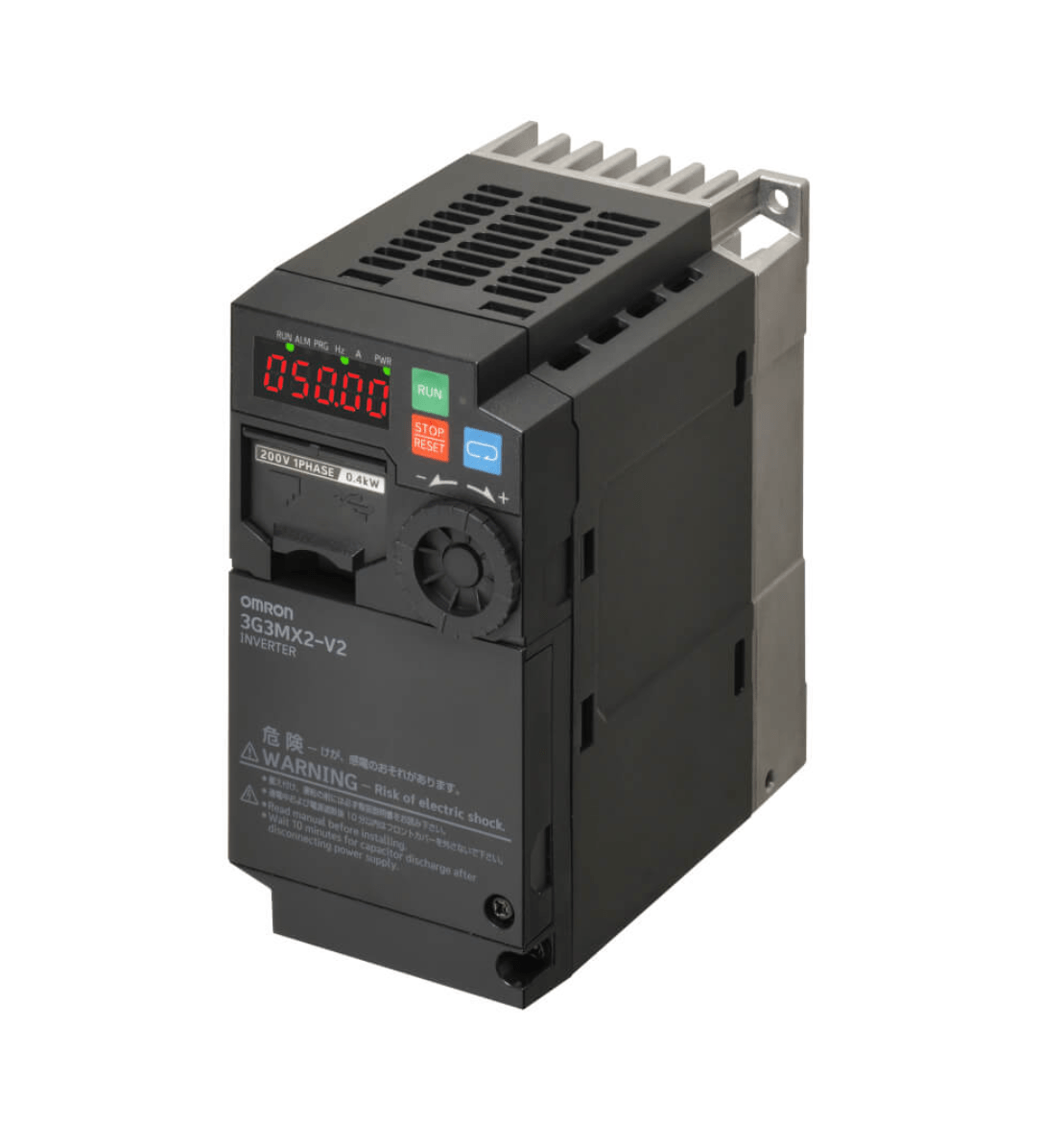

Boost Your Automation with the Omron 3G3MX2-A2002-EV2 Inverter

The compact 3G3MX2-A2002-EV2 AC drive, part of Omron’s MX2-EV2 Series, is designed for advanced motor control and efficiency. This article explores 3G3MX2-A2002-EV2 inverter specifications and industrial applications of 3G3MX2-A2002-EV2, highlighting its role in factory automation.

Omron 3G3MX2-A2002-EV2 Inverter Specifications

The high-efficiency 3G3MX2-A2002-EV2 inverter offers robust performance in a compact design. Key specifications are listed below.

| Feature | Detail |

|---|---|

| Power Capacity | 0.2/0.4 kW (ND/LD) |

| Input Voltage | 3-phase 200-240 VAC |

| Output Current | 1.6/1.9 A (ND/LD) |

| Control Method | Sensorless vector control |

| Communication | Modbus-RTU, optional EtherCAT |

| Max. Output Frequency | 590 Hz |

The 3G3MX2-A2002-EV2 motor control delivers 200% torque at 0.5 Hz, ensuring precise 3G3MX2-A2002-EV2 torque control for demanding applications.

Durability and Energy Efficiency

The reliable 3G3MX2-A2002-EV2 drive system, with an IP20 enclosure, excels in harsh industrial environments. The energy-saving 3G3MX2-A2002-EV2 inverter reduces power consumption, cutting operational costs. The durable 3G3MX2-A2002-EV2 industrial inverter requires minimal upkeep, supported by streamlined 3G3MX2-A2002-EV2 maintenance procedures.

Industrial Applications and Connectivity

Built for 3G3MX2-A2002-EV2 for factory automation, this inverter is ideal for 3G3MX2-A2002-EV2 for conveyor systems, pumps, fans, and mixers. The 3G3MX2-A2002-EV2 Modbus communication, with optional EtherCAT, enhances 3G3MX2-A2002-EV2 industrial networking. The 3G3MX2-A2002-EV2 system integration ensures seamless compatibility with PLCs, streamlining automation processes.

Simplified Installation and Support

The 3G3MX2-A2002-EV2 installation requirements are designed for quick setup. Compatible with CX-Drive software, the 3G3MX2-A2002-EV2 programming manual simplifies configuration. The 3G3MX2-A2002-EV2 troubleshooting guide reduces downtime, and the 3G3MX2-A2002-EV2 technical datasheet is available from trusted suppliers.

Why Choose the Omron 3G3MX2-A2002-EV2 Inverter?

The 3G3MX2-A2002-EV2 inverter combines energy efficiency, durability, and advanced 3G3MX2-A2002-EV2 sensorless vector control. Its compact design and versatile communication options make it perfect for modern automation. With 3G3MX2-A2002-EV2 system integration, your facility achieves optimal productivity.

Contact Trusted Suppliers Today

Reach out to reliable suppliers for competitive pricing and expert support. Request the 3G3MX2-A2002-EV2 technical datasheet to explore its capabilities. Elevate your operations with the Omron 3G3MX2-A2002-EV2 inverter and drive efficiency to new heights.

You can also visit our Omron Sensors page!

Precision and Stability for Compact Motor Applications

The Omron 3G3MX2-A2002-EV2 inverter is engineered to deliver reliable and highly accurate motor control for small-scale industrial systems. Thanks to its advanced sensorless vector control, the inverter maintains strong torque even at very low speeds, ensuring smooth and stable operation in precision-driven applications. This capability is especially valuable for processes requiring delicate speed adjustments or consistent torque delivery, such as dosing pumps, compact conveyor mechanisms, and small mixers.

With its ability to produce 200% torque at just 0.5 Hz, the 3G3MX2-A2002-EV2 supports demanding start-up conditions and rapid load transitions. This not only enhances machine responsiveness but also reduces mechanical wear, extending the lifespan of both motors and connected components. For facilities aiming to increase efficiency while maintaining operational consistency, this inverter provides an optimal balance of performance and reliability.

Smart Integration for Modern Factory Environments

Equipped with Modbus-RTU communication and optional EtherCAT support, the 3G3MX2-A2002-EV2 integrates seamlessly into various industrial control systems. Its compatibility with PLC-based architectures enhances system coordination and ensures efficient data flow across production lines. This streamlined communication structure helps operators monitor performance in real time and make quick adjustments when necessary.

The inverter’s compact size makes it easy to install even in tight panel spaces, while its CX-Drive software compatibility simplifies configuration and diagnostics. Additionally, its energy-efficient design helps reduce operational costs without compromising output quality. Whether used in small automation modules or as part of a larger system, the 3G3MX2-A2002-EV2 inverter delivers dependable, flexible, and cost-effective motor control for modern manufacturing environments.