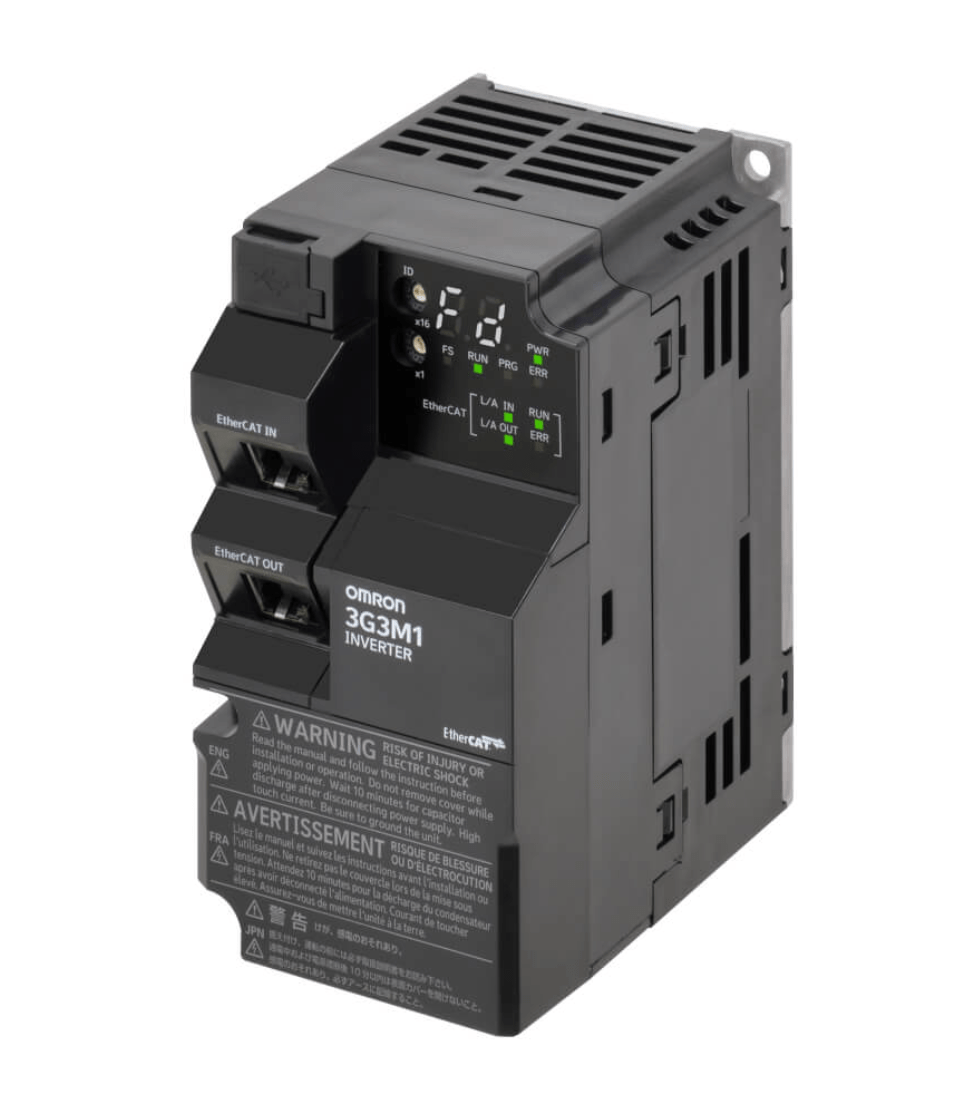

Omron 3G3M1-AB004-ECT Inverter: Advanced EtherCAT Solution for Industrial Automation

The Omron 3G3M1-AB004-ECT inverter combines exceptional performance, compact design, and cutting-edge EtherCAT communication capabilities to meet the demanding requirements of modern industrial automation. Transform your factory operations with this high-efficiency, network-ready drive solution.

Precision-Engineered for Modern Industry

The Omron 3G3M1-AB004-ECT inverter delivers superior performance in challenging industrial environments. Its compact dimensions, outstanding reliability, and sophisticated control features enhance production line efficiency while minimizing operational costs.

Built to withstand demanding conditions, this robust AC drive features comprehensive protection functions that ensure consistent, trouble-free operation throughout its extended service life. The 3G3M1-AB004-ECT incorporates all essential capabilities required for advanced factory automation systems.

Omron 3G3M1-AB004-ECT İnverter : Technical Specifications

| Feature | Value |

|---|---|

| Power Capacity | 0.4 kW |

| Input Voltage | Single/Three Phase 200-240V AC |

| Output Frequency | 0.1 – 400 Hz |

| Control Method | V/f Control, Open Loop Vector Control, Closed Loop Vector Control |

| Communication | EtherCAT |

| Cooling System | Natural Cooling |

| Protection Class | IP20 |

| STO Safety | IEC 61800-5-2 / SIL3 Compliant |

Advanced Features for Industry-Leading Performance

EtherCAT Communication Excellence

The Omron 3G3M1-AB004-ECT inverter features integrated EtherCAT communication, renowned for its high-speed, deterministic performance in industrial networks. This advanced protocol enables real-time control with minimal latency, providing precise synchronization across your entire automation system. EtherCAT technology simplifies network architecture while delivering exceptional data throughput, making it ideal for sophisticated motion control applications.

Sophisticated Motor Control

With multiple control algorithms including V/f, open-loop vector, and closed-loop vector control, the 3G3M1-AB004-ECT delivers precise speed and torque regulation across a wide operational range. Advanced motor identification routines optimize performance parameters automatically, ensuring optimal efficiency regardless of connected motor type. Dynamic acceleration and deceleration profiles allow fine-tuning of motion characteristics to match specific application requirements.

Energy-Saving Innovation

The 3G3M1-AB004-ECT incorporates intelligent energy optimization functions that significantly reduce power consumption. Its automatic energy-saving mode continuously adjusts operating parameters based on actual load conditions, minimizing losses during partial-load operation. This smart technology delivers substantial cost savings, particularly in variable-torque applications such as pump and fan systems.

Industrial Applications

The 3G3M1-AB004-ECT inverter excels across diverse industrial applications:

Advanced Conveyor Systems

Precise speed control and sophisticated acceleration/deceleration profiles ensure smooth material handling in conveyor applications. The EtherCAT communication capability enables perfect synchronization between multiple drives in complex conveyor systems, optimizing material flow while minimizing mechanical stress.

High-Performance Pump Systems

Dedicated pump control functions optimize pressure and flow regulation in fluid handling applications. Built-in PID control with sleep mode functionality improves energy efficiency while maintaining precise process variables. Multiple pump cascade control capability enables sophisticated management of pump stations with varying demand profiles.

Precision Manufacturing Equipment

High-speed EtherCAT communication and sophisticated motion control algorithms make the 3G3M1-AB004-ECT ideal for precision manufacturing applications. Exceptional positioning accuracy and repeatable torque control ensure consistent quality in demanding production processes.

Installation and System Integration

The 3G3M1-AB004-ECT offers streamlined installation and commissioning procedures. Its compact footprint conserves valuable control panel space, while multiple mounting options accommodate diverse installation requirements.

Comprehensive configuration tools simplify setup and parameterization. The intuitive programming interface reduces commissioning time even for complex applications, minimizing downtime during system deployment.

Installation Requirements

| Parameter | Requirement |

|---|---|

| Ambient Temperature | -10°C to +50°C |

| Humidity | 95% RH or less (non-condensing) |

| Vibration | 5.9 m/s² (0.6G) 10-55 Hz |

| Protection | Environment protected from dust and moisture |

| Altitude | Full performance up to 1000m (derating required at higher altitudes) |

| Network | EtherCAT network infrastructure with standard Cat5e or higher cables |

STO Safety Features

The 3G3M1-AB004-ECT incorporates advanced STO (Safe Torque Off) functionality compliant with IEC 61800-5-2 standards. This critical safety feature ensures reliable power removal from the motor in emergency situations, protecting both personnel and equipment.

With SIL3-compliant design, the drive meets stringent safety standards and provides high reliability in risk assessments. Integration of safety functions within the drive reduces dependency on external safety components, lowering overall system complexity and cost.

Maintenance and Troubleshooting

Engineered for exceptional reliability, the 3G3M1-AB004-ECT minimizes maintenance requirements throughout its extended service life. Comprehensive self-diagnostic functions continuously monitor critical parameters, providing early warning of potential issues before they impact production.

An advanced error logging system with timestamped events facilitates rapid troubleshooting when required. The EtherCAT interface enables remote diagnostics and parameter adjustment, reducing the need for on-site service visits and minimizing downtime.

Conclusion: Transforming Industrial Automation

The 3G3M1-AB004-ECT inverter represents the pinnacle of modern drive technology, combining high-performance motor control with advanced EtherCAT communication in a compact, reliable package. Its sophisticated features enhance production efficiency while reducing operational expenses across diverse industrial applications.

The integration of EtherCAT technology ensures seamless compatibility with Industry 4.0 initiatives, providing the high-speed, deterministic communication essential for next-generation manufacturing systems. Its robust construction and comprehensive protection features guarantee dependable operation even in challenging industrial environments.

Elevate your automation infrastructure with the Omron 3G3M1-AB004-ECT inverter and experience the benefits of cutting-edge drive technology with industry-leading network capabilities.

You can also visit our Omron Sensors page!

Enhanced Performance for Compact Automation Systems

The Omron 3G3M1-AB004-ECT inverter delivers remarkable stability and precision in compact automation environments. Its ability to maintain high torque at low speeds makes it ideal for applications requiring delicate motion control, such as feeder mechanisms, indexing systems, and small-scale assembly machines. With EtherCAT providing seamless communication, the inverter synchronizes effortlessly with other devices on the network, ensuring uninterrupted and coordinated machine operation.

Optimized Efficiency for Continuous Operation

Designed for long-term reliability, the 3G3M1-AB004-ECT includes intelligent energy management functions that minimize power usage during fluctuating load conditions. This reduces operational expenses without compromising performance. In demanding environments, built-in protection features such as overload detection, temperature monitoring, and STO safety functions contribute to uninterrupted system performance. These capabilities help maintain steady production flow and extend the lifespan of connected motors.

Seamless Integration with Modern Industrial Networks

With full EtherCAT support, the 3G3M1-AB004-ECT integrates smoothly into sophisticated industrial control architectures. Real-time data transfer and fast response times enable precise motor coordination across multiple axes, making this model highly suitable for advanced manufacturing lines. The inverter’s compatibility with standard automation platforms simplifies configuration while offering extensive monitoring options—allowing engineers to fine-tune performance parameters and maintain full operational visibility throughout the production process.