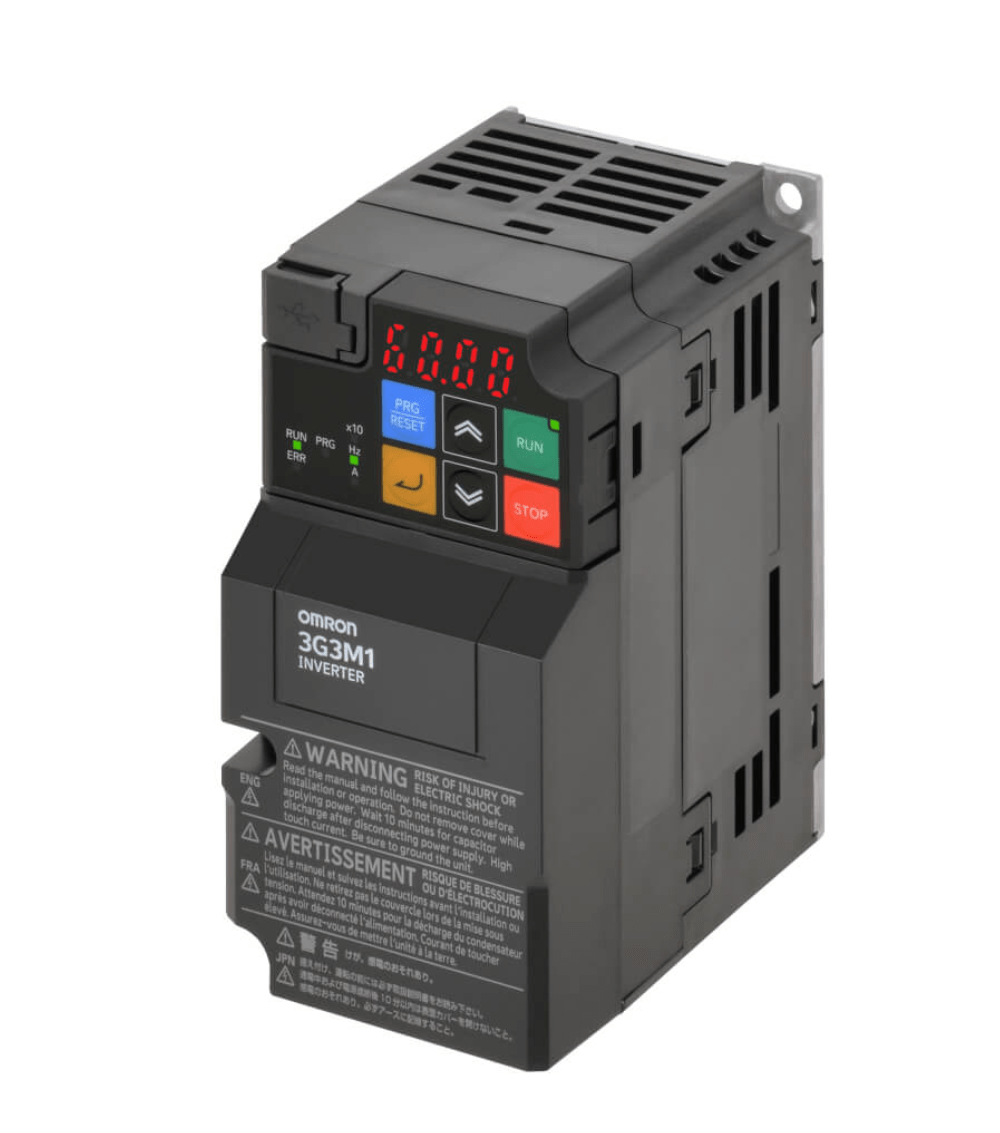

Enhance Your Automation with the Omron 3G3M1-AB002 Inverter

The Compact 3G3M1-AB002 AC drive from Omron’s M1 Series is a high-performance solution for industrial automation. This article explores 3G3M1-AB002 inverter specifications and Industrial applications of 3G3M1-AB002, highlighting its value for your factory.

Technical Specifications of Omron 3G3M1-AB002 Inverter

The High-efficiency Omron 3G3M1-AB002 inverter delivers robust performance in a compact package. Review its key specifications in the table below.

| Feature | Detail |

|---|---|

| Power Rating | 0.2/0.4 kW (HD/ND) |

| Input Voltage | 1-phase 200-240 VAC |

| Output Current | 1.6/1.9 A (HD/ND) |

| Control Method | OLV/CLV control |

| Communication | Modbus-RTU, optional EtherCAT |

| Max Output Frequency | 590 Hz |

3G3M1-AB002 motor control provides 200% torque at 0 Hz, ensuring precise 3G3M1-AB002 torque control for demanding applications.

Reliability and Energy Efficiency

The Reliable 3G3M1-AB002 drive system features an IP20 enclosure and 3G3M1-AB002 STO safety features for secure operation in tough environments. The Energy-saving 3G3M1-AB002 inverter reduces power consumption, lowering operational costs. The Durable 3G3M1-AB002 industrial inverter minimizes 3G3M1-AB002 maintenance procedures, ensuring long-term performance.

Industrial Applications and Connectivity

Designed for 3G3M1-AB002 for factory automation, this inverter excels in 3G3M1-AB002 for conveyor systems, feeders, and small-scale automation tasks. Its 3G3M1-AB002 communication protocols, including Modbus-RTU and optional EtherCAT, support robust 3G3M1-AB002 industrial networking. Seamless 3G3M1-AB002 system integration with PLCs enhances factory efficiency.

Easy Setup and Support

3G3M1-AB002 installation requirements are streamlined for quick deployment. The 3G3M1-AB002 programming manual, compatible with Sysmac Studio, simplifies configuration. The 3G3M1-AB002 troubleshooting guide provides practical solutions to minimize downtime. Request the 3G3M1-AB002 technical datasheet from trusted suppliers for comprehensive details.

Why Choose the Omron 3G3M1-AB002 Inverter?

The 3G3M1-AB002 inverter combines energy efficiency, durability, and advanced control, making it ideal for small-scale automation. Its compact design, STO safety features, and flexible communication protocols set it apart. With 3G3M1-AB002 system integration, your factory achieves peak performance.

Partner with Trusted Suppliers Today

Connect with reliable suppliers for competitive pricing and expert support. Request the 3G3M1-AB002 technical datasheet to unlock its full potential. Transform your production with the 3G3M1-AB002 inverter and achieve new levels of efficiency.

You can also visit our Omron Sensors page!

Optimized Motion Control for Lightweight Industrial Processes

The 3G3M1-AB002 inverter is engineered to deliver stable and precise motor operation in compact automation systems. Its ability to maintain high torque even at zero speed ensures smooth startups and accurate positioning, especially in applications that require gentle material handling or precise feed control. This performance is particularly valuable in small conveyor lines, pick-and-place systems, and compact packaging machinery where consistent operation is essential for maintaining product quality and workflow stability.

Reliable Operation in Challenging Environments

Built with durability in mind, the 3G3M1-AB002 inverter provides dependable operation even in demanding industrial settings. The IP20 enclosure and integrated STO (Safe Torque Off) feature enhance equipment and operator safety by ensuring controlled shutdowns during emergency conditions. Additionally, its efficient thermal design prevents overheating, extending component lifespan and reducing maintenance needs. This makes the inverter a strong choice for facilities that require continuous operation with minimal intervention.

Smart Connectivity for Modern Automation Networks

With support for Modbus-RTU and optional EtherCAT communication, the 3G3M1-AB002 inverter offers flexible integration into both traditional and advanced automation infrastructures. These communication options provide real-time data exchange, allowing operators to monitor performance, adjust parameters, and diagnose issues quickly. Seamless PLC compatibility further enhances system coordination, enabling manufacturers to optimize energy usage and improve overall productivity in compact machine environments. This adaptability makes the inverter ideal for future-ready automation strategies.