Boost Your Automation with Omron 3G3M1-A4055-ECT Inverter 🚀

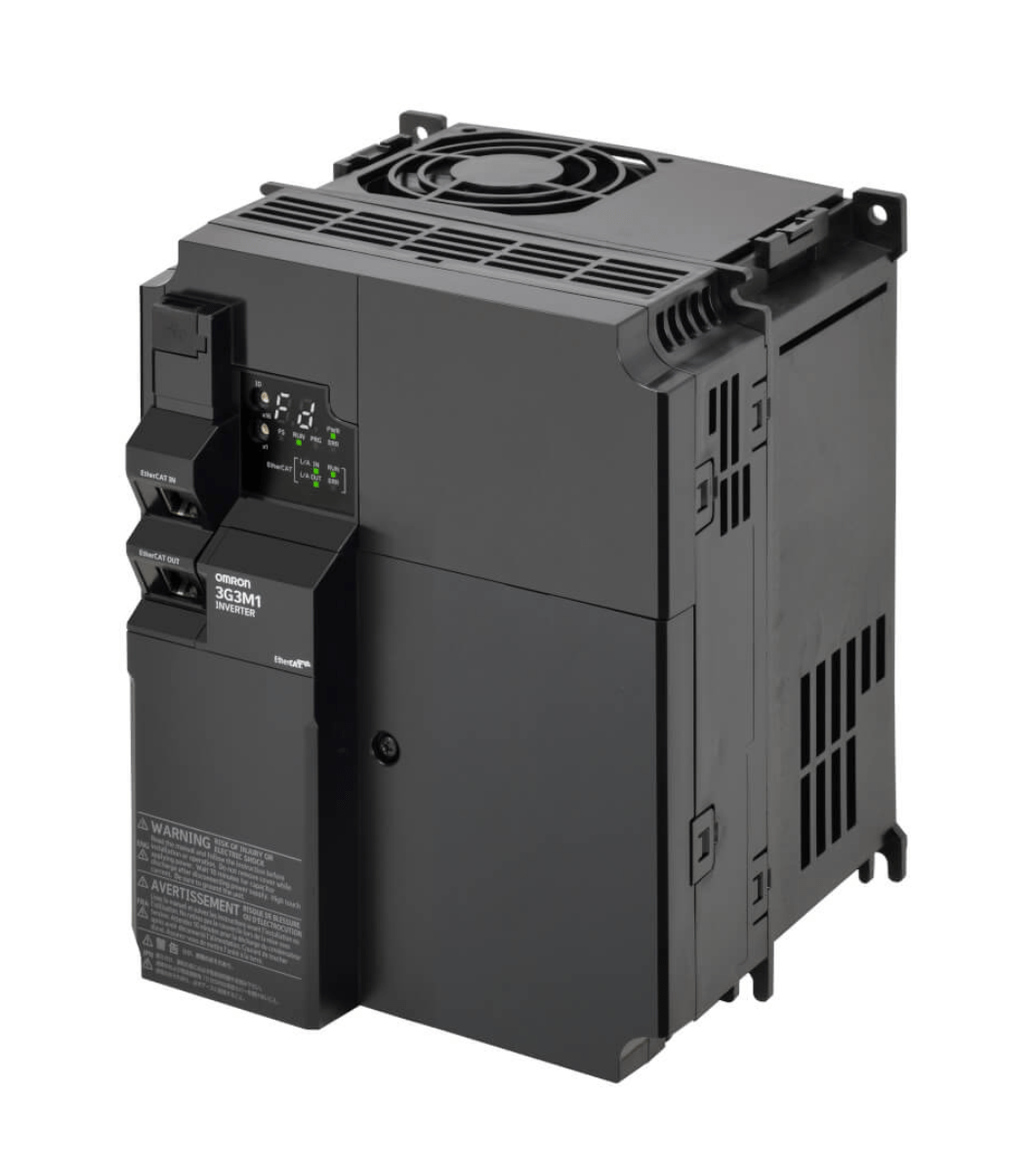

The Compact 3G3M1-A4055-ECT AC drive from Omron’s M1 Series is a top-tier solution for industrial automation. 🌟 This article explores Omron 3G3M1-A4055-ECT inverter specifications and Industrial applications of 3G3M1-A4055-ECT, highlighting why it’s a must-have for your factory! 💪

Technical Specifications of Omron 3G3M1-A4055-ECT Inverter

The High-efficiency Omron 3G3M1-A4055-ECT inverter delivers outstanding performance in a compact package. Check out its key specs in the table below! 📊

| Feature | Detail |

|---|---|

| Power Rating | 5.5/7.5 kW (HD/ND) |

| Input Voltage | 3-phase 380-480 VAC |

| Output Current | 14.8/17.5 A (HD/ND) |

| Control Method | OLV/CLV control |

| Communication | EtherCAT, STO (FSoE + wired) |

| Max Output Frequency | 590 Hz |

3G3M1-A4055-ECT motor control provides 200% torque at 0 Hz, ensuring precise 3G3M1-A4055-ECT torque control for demanding tasks. 🎯

Reliability and Energy Efficiency

The Reliable 3G3M1-A4055-ECT drive system excels in tough environments, featuring an IP20 enclosure and 3G3M1-A4055-ECT STO safety features for enhanced safety. 🔒 The Energy-saving 3G3M1-A4055-ECT inverter reduces power usage, saving you money. 💰 Its Durable 3G3M1-A4055-ECT industrial inverter design minimizes 3G3M1-A4055-ECT maintenance procedures, ensuring long-term performance. 🛠️

Industrial Applications and Connectivity

Built for 3G3M1-A4055-ECT for factory automation, this inverter shines in 3G3M1-A4055-ECT for conveyor systems, stackers, and winders. 🚚 Its 3G3M1-A4055-ECT EtherCAT communication enables fast data transfer, powering 3G3M1-A4055-ECT industrial networking. 🌐 Seamless 3G3M1-A4055-ECT system integration with PLCs makes it a factory favorite! 🤝

Easy Setup and Support

3G3M1-A4055-ECT installation requirements are optimized for quick deployment. ⚡ The 3G3M1-A4055-ECT programming manual, compatible with Sysmac Studio, simplifies configuration. 📖 The 3G3M1-A4055-ECT troubleshooting guide offers practical fixes to keep downtime low. 🛠️ Request the 3G3M1-A4055-ECT technical datasheet from trusted suppliers for all details! 📄

Why Choose the Omron 3G3M1-A4055-ECT Inverter?

The Omron 3G3M1-A4055-ECT inverter blends energy efficiency, durability, and advanced control, making it ideal for modern automation. Its compact design, EtherCAT support, and STO features set it apart. 🌟 With 3G3M1-A4055-ECT system integration, your factory will run at peak efficiency! 😎

Partner with Top Suppliers Today

Connect with trusted suppliers for competitive pricing and expert support. Request the 3G3M1-A4055-ECT technical datasheet to unlock its full potential. Transform your production with the Omron 3G3M1-A4055-ECT inverter and soar to new heights! 🚀🌟

You can also visit our Omron Sensors page!

Advanced Motion Control for Precision-Driven Operations

The Omron 3G3M1-A4055-ECT inverter is designed to deliver highly accurate motor control, making it an excellent choice for systems that require synchronized and predictable motion. Its advanced vector control ensures stable torque output even under variable load conditions, resulting in smoother transitions and consistent machine behavior. This precision is especially valuable for automated production lines, packaging machinery, lifting mechanisms, and complex conveyor applications where reliability directly affects output quality.

Robust Protection Architecture for Continuous Performance

To support demanding industrial environments, the 3G3M1-A4055-ECT integrates a comprehensive protection system. Built-in safeguards such as overload protection, thermal monitoring, under-voltage detection, and short-circuit prevention help maintain stable operation and reduce equipment wear. The STO (Safe Torque Off) functionality further enhances safety by providing immediate torque cutoff during emergency stops. This layered protection not only improves equipment longevity but also minimizes unplanned downtime, keeping operations running efficiently.

Seamless Integration for Modern Automation Networks

With EtherCAT communication capabilities, the 3G3M1-A4055-ECT inverter is perfectly suited for advanced automation environments requiring real-time data exchange. Users can customize acceleration curves, torque limits, and communication parameters to meet specific application needs, making the drive adaptable to a variety of industrial systems. Whether upgrading an existing line or building a new automated process, this inverter delivers the flexibility, speed, and interoperability required for next-generation industrial automation.