Omron 3G3M1-A4030-ECT Inverter: Revolutionizing Industrial Motor Control

The 3G3M1-A4030-ECT is an advanced compact AC drive delivering high-efficiency motor control with EtherCAT connectivity, perfect for modern factory automation and industrial applications demanding precision and reliability.

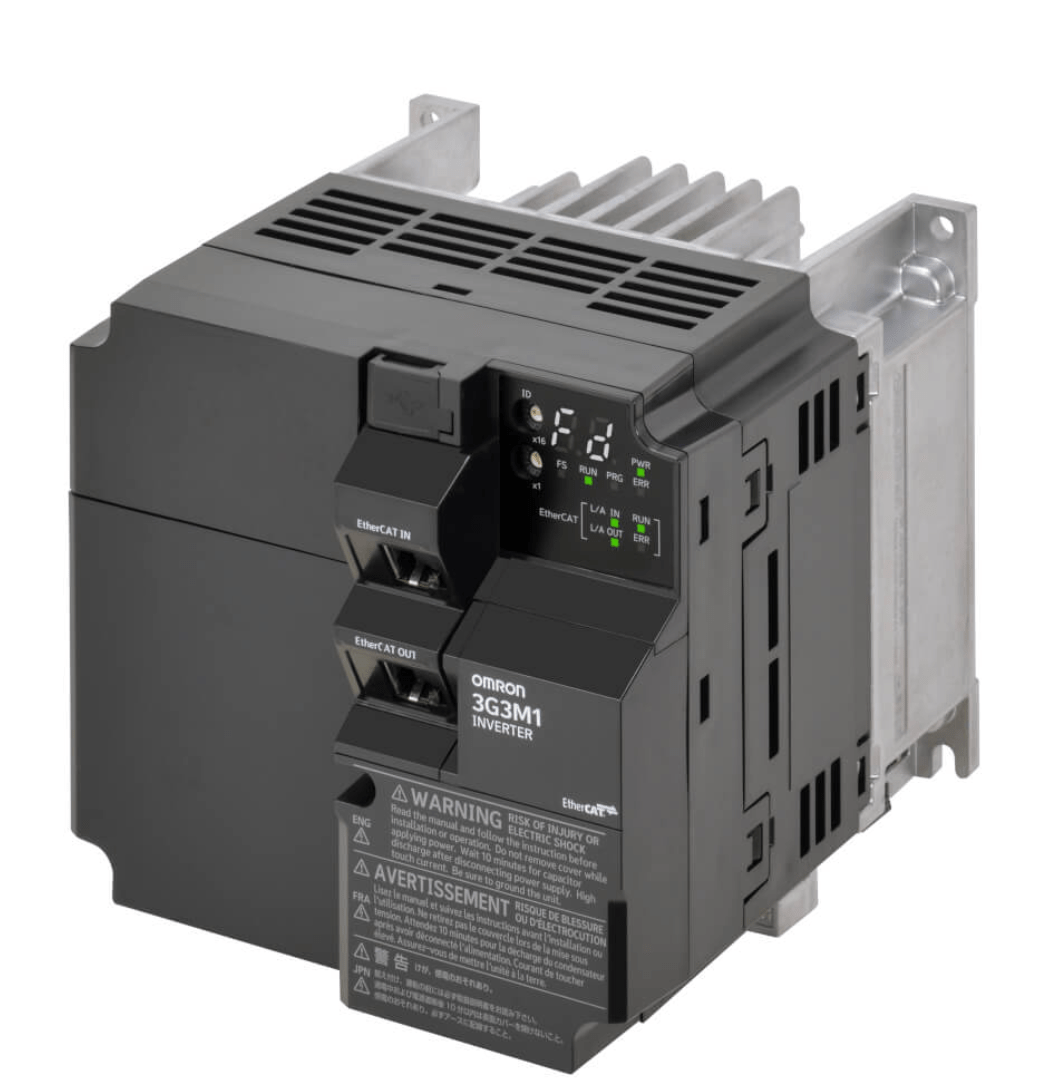

The compact and powerful Omron 3G3M1-A4030-ECT inverter drive system for industrial automation applications

🔋Omron 3G3M1-A4030-ECT Inverter : High-Efficiency Drive System for Industrial Applications

The Omron 3G3M1-A4030-ECT inverter epresents the pinnacle of industrial motor control technology, combining compact design with powerful performance capabilities. This versatile AC drive is engineered specifically for demanding industrial environments where reliability, efficiency, and precise control are paramount.

With its advanced EtherCAT communication capabilities, the 3G3M1-A4030-ECT seamlessly integrates into factory automation networks, providing real-time control and monitoring for optimal production performance. The unit’s sophisticated torque control algorithms ensure smooth operation across various load conditions, making it ideal for conveyor systems, packaging equipment, and other industrial machinery.

⚙️ Technical Specifications and Features

The 3G3M1-A4030-ECT is packed with features that make it a standout solution for industrial drive applications. Its compact footprint saves valuable space in control cabinets while delivering impressive power output and control precision.

| Specification | Details |

|---|---|

| Power Rating | 3.0 kW |

| Input Voltage | 380-480V AC, 3-phase |

| Output Frequency | 0.1 to 400 Hz |

| Communication Protocol | EtherCAT |

| Control Methods | V/f control, Open-loop vector control, Closed-loop vector control |

| Safety Features | STO (Safe Torque Off) |

| Overload Capacity | 150% for 60 seconds |

| Dimensions (WxHxD) | 140 x 260 x 170 mm |

| Protection Rating | IP20 |

🏭 Industrial Applications and System Integration

Perfect for Factory Automation

The Omron 3G3M1-A4030-ECT inverter excels in factory automation environments where precision motor control directly impacts production quality and efficiency. Its robust design and reliable performance make it the preferred choice for system integrators and machine builders seeking dependable drive solutions.

Conveyor Systems

For conveyor applications, the 3G3M1-A4030-ECT provides smooth acceleration and deceleration profiles, ensuring gentle handling of products while maintaining precise speed control. The drive’s advanced torque control capabilities enable consistent performance even with varying loads, critical for maintaining production line balance.

Energy-Saving Operation

Energy efficiency is built into every aspect of the 3G3M1-A4030-ECT design. The inverter features specialized energy-saving algorithms that automatically optimize motor operation based on load conditions, significantly reducing power consumption during partial load operations without sacrificing performance.

🔄 EtherCAT Communication and Networking

The EtherCAT communication capability of the 3G3M1-A4030-ECT drive enables seamless integration into modern industrial networks. This high-speed industrial Ethernet protocol provides:

- Real-time control with cycle times as low as 100 μs

- Deterministic communication for precise synchronization

- Simple configuration and commissioning

- Comprehensive diagnostics capabilities

- Reduced wiring complexity compared to traditional systems

🛠️ Installation and Maintenance

The 3G3M1-A4030-ECT is designed with ease of installation and maintenance in mind. Its plug-and-play connectivity options reduce commissioning time, while the comprehensive diagnostic features help identify and resolve issues quickly to minimize downtime.

Installation Requirements

For optimal performance, the inverter should be installed in a well-ventilated control cabinet with adequate clearance for cooling. The unit’s compact design makes it ideal for installations where space is at a premium without compromising on performance or reliability.

Preventive Maintenance

Regular maintenance procedures are straightforward, primarily involving inspection of cooling fans, checking electrical connections, and ensuring proper ventilation. The drive’s built-in diagnostic functions continuously monitor critical parameters, alerting operators to potential issues before they cause downtime.

🔒 Safety Features and Reliability

Safety is paramount in industrial environments, and the 3G3M1-A4030-ECT delivers with its comprehensive safety features, including Safe Torque Off (STO) functionality. This critical safety feature ensures that the drive will not generate torque in the motor in emergency situations, protecting both equipment and personnel.

Built to last, the Omron 3G3M1-A4030-ECT inverter features durable components designed to withstand the rigors of industrial environments, including temperature fluctuations, vibration, and electrical noise. This robust construction translates to extended service life and reduced total cost of ownership.

📊 Conclusion: The Future of Industrial Motor Control

The Omron 3G3M1-A4030-ECT inverter represents the next generation of industrial drive technology, combining high-efficiency operation, advanced communication capabilities, and robust design in a compact package. Whether for new installations or system upgrades, this versatile inverter delivers the performance, reliability, and integration capabilities demanded by modern industrial applications.

For technical support, comprehensive programming guides, and troubleshooting assistance, our dedicated team of drive specialists is ready to help you maximize the potential of your Omron 3G3M1-A4030-ECT inverter investment.

You can also visit our Omron Sensors page!

Enhanced Control Precision for Complex Industrial Processes

The Omron 3G3M1-A4030-ECT inverter delivers highly refined motor control that supports even the most demanding automation environments. Its advanced vector control algorithms offer stable torque production at low speeds, enabling smooth and predictable motion profiles. This level of precision is particularly valuable in applications such as packaging machinery, automated lifting systems, and indexing equipment, where consistent motion directly impacts product quality and line efficiency. With its responsiveness to dynamic load changes, the inverter ensures optimal control across varied industrial processes.

Optimized System Performance with Built-In Intelligence

Beyond basic motor operation, the 3G3M1-A4030-ECT incorporates intelligent functions designed to enhance system-wide performance. Features such as automatic energy optimization, adaptive load compensation, and real-time monitoring help maintain stable operation under shifting production conditions. These functions reduce unnecessary energy usage while maximizing throughput, making the inverter an ideal solution for facilities aiming to balance performance with operational cost efficiency.

Flexible Integration and Future-Ready Automation

Thanks to its EtherCAT support and extensive parameter configuration options, the inverter integrates seamlessly into today’s modular and interconnected automation environments. Users can tailor control modes, acceleration profiles, and communication settings to fit specific machine requirements. This flexibility makes the 3G3M1-A4030-ECT suitable for both retrofitting older systems and implementing next-generation automation architectures. Its robust construction and versatile control capabilities position it as a reliable, future-proof component in modern industrial systems.