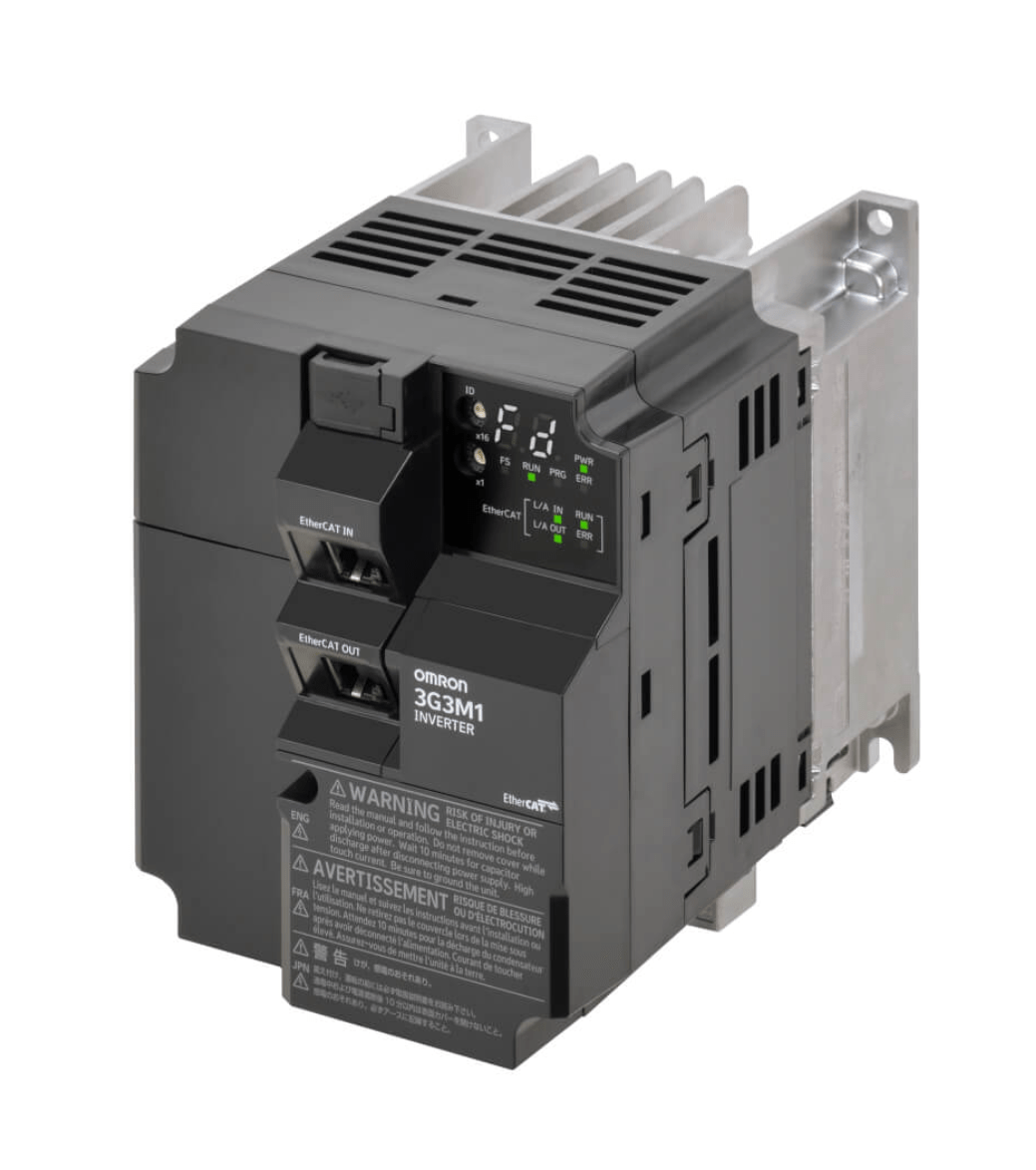

OMRON 3G3M1-A4015-ECT Inverter : Advanced Industrial Inverter with EtherCAT Communication

OMRON 3G3M1-A4015-ECT inverter : Compact and high-performance industrial inverter with EtherCAT connectivity for modern factory automation

In today’s high-speed industrial environment, precision, reliability, and connectivity are paramount for maintaining competitive edge. The OMRON 3G3M1-A4015-ECT inverter stands out as a premier solution, combining advanced motor control with seamless EtherCAT communication capabilities. This compact yet powerful AC drive delivers exceptional performance while optimizing energy efficiency for a wide range of industrial applications.

✨ Key Benefits at a Glance:

- 🔌 Integrated EtherCAT communication

- 💪 Robust motor control capabilities

- 📏 Compact, space-saving design

- 💡 Energy-efficient operation

- 🛡️ Advanced STO safety features

- 🔄 Versatile industrial applications

Omron 3G3M1-A4015-ECT Inverter : Technical Specifications

The OMRON 3G3M1-A4015-ECT inverter delivers exceptional performance with its comprehensive feature set designed for modern industrial environments. Let’s examine the core specifications that make this inverter a standout solution:

| Specification | Value |

|---|---|

| Power Capacity | 1.5 kW / 2 HP |

| Input Voltage | 3-Phase 380-480 VAC |

| Output Current | 4.1A |

| Frequency Range | 0.1-400 Hz |

| Control Methods | V/f, Open Loop Vector, Closed Loop Vector |

| Communication | Built-in EtherCAT |

| Overload Capacity | 150% – 1 minute, 200% – 3 seconds |

| Protection Rating | IP20 |

| Dimensions (W×H×D) | 140×128×129 mm |

| Safety Features | Safe Torque Off (STO) – SIL3/PLe |

🏭 Industrial Applications of 3G3M1-A4015-ECT

The versatility of the OMRON 3G3M1-A4015-ECT inverter makes it suitable for a wide range of industrial applications:

Factory Automation

In modern manufacturing facilities, the Omron 3G3M1-A4015-ECT inverter provides precise control for assembly lines, packaging equipment, and material handling systems. Its EtherCAT connectivity ensures seamless integration with factory-wide control networks, enabling real-time monitoring and control.

Conveyor Systems

The superior torque control capabilities make this inverter ideal for conveyor applications, offering smooth acceleration and deceleration while maintaining precise speed control even under varying load conditions.

HVAC Systems

For industrial climate control applications, the 3G3M1-A4015-ECT offers energy-efficient fan and pump control with built-in PID functionality, optimizing performance while reducing energy consumption.

Textile Machinery

The high-precision speed control of the 3G3M1-A4015-ECT makes it perfect for textile applications where consistent tension and accurate positioning are critical for product quality.

⚡ High-Efficiency Motor Control

The 3G3M1-A4015-ECT excels in motor control, offering:

Advanced Torque Control

With vector control technology, this inverter delivers exceptional torque performance even at low speeds. The proprietary control algorithms maintain stable operation under dynamic load conditions, ensuring smooth and precise motor response.

Energy-Saving Features

The auto-energy optimization function continuously adjusts output voltage according to load conditions, minimizing power consumption while maintaining optimal performance. This translates to significant energy savings in applications with variable loads.

- Automatic energy optimization function

- Sleep mode for low-demand periods

- Regenerative energy recovery

- High efficiency at partial loads

🔄 EtherCAT Communication and System Integration

The integrated EtherCAT interface in the 3G3M1-A4015-ECT provides several advantages for modern industrial systems:

- High-speed real-time communication (100 Mbps)

- Microsecond-level synchronization

- Easy integration with EtherCAT-based control systems

- Reduced wiring complexity

- Comprehensive diagnostics capabilities

- Remote monitoring and parameter adjustment

This connectivity makes the 3G3M1-A4015-ECT an ideal component in Industry 4.0 environments, where seamless data exchange between system components is essential for optimized production.

🛡️ Safety and Protection Features

OMRON 3G3M1-A4015-ECT incorporates comprehensive safety functions designed for harsh industrial environments:

STO (Safe Torque Off) Technology

The integrated STO functionality complies with SIL3/PLe safety standards, allowing for safe system integration in applications where emergency stopping is required. This eliminates the need for external safety components, reducing system complexity and cost.

Comprehensive Protection Functions

- Overcurrent and overvoltage protection

- Undervoltage detection

- Motor thermal protection

- Ground fault detection

- Phase loss protection

- Short circuit protection

- Electronic thermal overload relay

These protection features ensure both the inverter and connected motor are safeguarded against abnormal operating conditions, maximizing system reliability and longevity.

🔧 Easy Installation and Maintenance

The 3G3M1-A4015-ECT is designed for simplified installation and maintenance:

- Compact dimensions for space-saving installation

- User-friendly operator panel

- Quick-connect terminals

- Removable control board for easy replacement

- Comprehensive fault logging system

- PC-based configuration software

- Predictive maintenance functions

These features minimize downtime and simplify troubleshooting, ensuring your production remains operational with minimal interruptions.

Conclusion: The Right Choice for Your Industrial Needs

The OMRON 3G3M1-A4015-ECT inverter combines advanced motor control capabilities, integrated EtherCAT communication, and comprehensive safety features in a compact, energy-efficient package. Its versatility makes it suitable for a wide range of industrial applications, while its reliability ensures long-term operation with minimal maintenance.

Backed by OMRON’s global support network and proven reliability, the 3G3M1-A4015-ECT represents an excellent investment for industrial operations looking to enhance performance, reduce energy consumption, and prepare for the future of connected manufacturing.

You can also visit our Omron Sensors page!

🌐 Seamless Integration with Modern Automation Platforms

The Omron 3G3M1-A4015-ECT inverter is engineered for effortless integration into advanced automation ecosystems. Its built-in EtherCAT interface enables real-time communication across distributed control systems, ensuring synchronized operation of multiple drives, sensors, and PLCs. This high-speed connectivity significantly improves cycle times and enhances overall system responsiveness.

Thanks to its compatibility with Omron’s Sysmac Studio environment, configuration and parameter management become streamlined and intuitive. Users can easily monitor performance, adjust control settings, and diagnose issues without interrupting production. This makes the 3G3M1-A4015-ECT an ideal choice for smart factories adopting Industry 4.0 technologies.

🔍 Enhanced Performance in Demanding Environments

Designed to withstand harsh industrial conditions, the 3G3M1-A4015-ECT maintains stable performance even under fluctuating loads and extreme duty cycles. Its optimized cooling system and intelligent thermal protection extend the lifespan of both the inverter and connected motors. With its high overload capacity (up to 200% for 3 seconds), it supports demanding applications that require immediate torque response and precise speed regulation.

Whether used in high-speed conveyor lines, precision winding machines, or load-sensitive lifting systems, the inverter ensures smooth, accurate, and energy-efficient operation. Its reliability and advanced diagnostics reduce unplanned downtime and support continuous production efficiency.