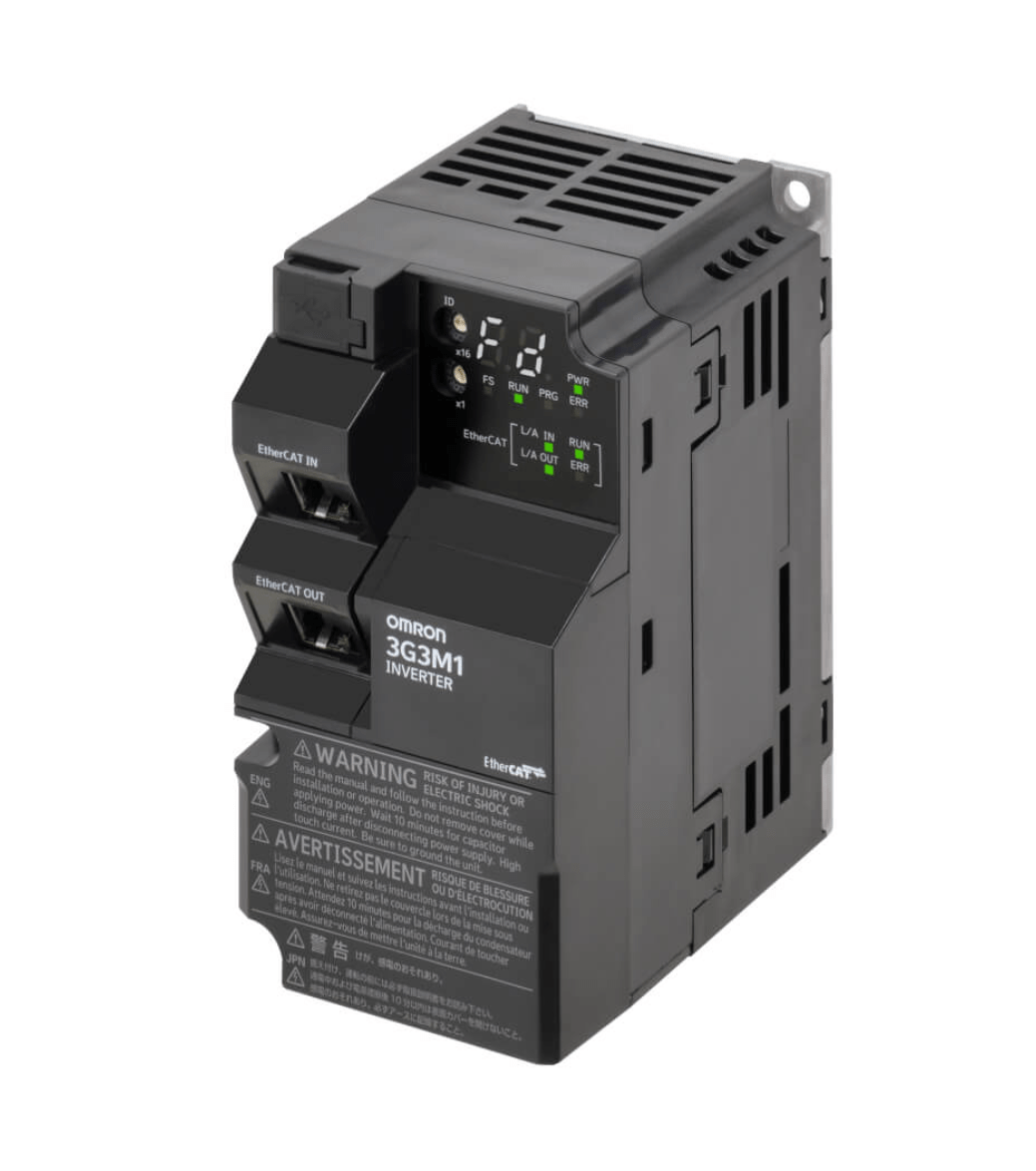

Omron 3G3M1-A2004-ECT Inverter: Compact Power for Industrial Automation

The Omron 3G3M1-A2004-ECT inverter is a high-efficiency variable frequency drive (VFD) designed for advanced industrial automation. This compact AC drive, tailored for single-phase 200 VAC systems, delivers precise motor control and energy savings for applications like conveyor systems, feeders, and winders. With EtherCAT communication, robust torque control, and open/closed loop control, the Omron 3G3M1-A2004-ECT inverter ensures reliable performance in factory automation. Its technical specifications, easy installation requirements, and system integration capabilities make it an ideal choice for optimizing industrial processes.

Technical Specifications of the Omron 3G3M1-A2004-ECT Inverter

The 3G3M1-A2004-ECT combines compact design with powerful performance. Below is a table of its key technical specifications:

| Parameter | Specification |

|---|---|

| Power Capacity | 0.4 kW (HD) / 0.55 kW (ND) |

| Input Voltage | Single-phase 200-240 VAC |

| Output Current | 3.0 A (HD) / 3.5 A (ND) |

| Frequency Range | 0.1-590 Hz |

| Control Method | Open/Closed Loop Vector (OLV/CLV) |

| Protection Class | IP20 |

| Safety Features | STO (ISO 13849-1, Cat 3/PLd, FSoE + wired) |

Industrial Applications and Key Features

Energy Savings and Open/Closed Loop Control

The energy-saving Omron 3G3M1-A2004-ECT inverter optimizes power consumption in conveyor systems, hoists, and stackers, reducing operational costs. Its open/closed loop control delivers 200% torque at 0 Hz, ensuring precise motor control for cyclic tasks. Compatible with both induction (IM) and permanent magnet (PM) motors, this inverter supports diverse industrial applications, including food processing, material handling, and textile production.

Advanced Torque and Positioning Control

The 3G3M1-A2004-ECT excels in torque control and positioning control, making it ideal for winders, rotary tables, and presses. Its compact design simplifies installation in space-constrained environments, while its durable construction ensures reliable operation under heavy loads, enhancing the longevity of the drive system.

EtherCAT Communication and System Integration

With built-in EtherCAT communication, the 3G3M1-A2004-ECT ensures seamless industrial network connectivity. This enables real-time data exchange and integration with PLCs and other automation systems, streamlining factory automation. The programming guide, compatible with Omron’s unified software, simplifies configuration, while the technical datasheet provides detailed setup instructions, ensuring efficient system integration.

Installation and Maintenance

The 3G3M1-A2004-ECT’s installation requirements are straightforward, thanks to its IP20 protection class and compact design. Proper ventilation ensures optimal performance in demanding environments. The troubleshooting guide, available in Omron’s official resources, offers practical solutions to minimize downtime. Regular maintenance, such as checking terminals and cooling fans, ensures the durable industrial inverter’s long-term reliability.

Safety and Durability

Equipped with Safe Torque Off (STO) compliant with ISO 13849-1 (Cat 3/PLd) and Fail-Safe over EtherCAT (FSoE), the 3G3M1-A2004-ECT prioritizes safety. CE, UL, and cUL certifications confirm its adherence to global standards. Protections against overcurrent, overvoltage, and thermal overload ensure the drive’s robust performance in harsh industrial conditions.

Why Choose the Omron 3G3M1-A2004-ECT Inverter?

The reliable 3G3M1-A2004-ECT drive system is a top choice for factory automation. Its compact, energy-saving design, combined with advanced torque control and EtherCAT connectivity, delivers exceptional performance across conveyor systems, hoists, and winders. Omron’s technical datasheet and troubleshooting guide simplify installation and maintenance, ensuring operational efficiency. Upgrade your automation processes with the 3G3M1-A2004-ECT and achieve significant energy savin

You can also visit our Omron Sensors page!

Enhanced Performance for Modern Automation Lines

The Omron 3G3M1-A2004-ECT inverter is engineered to meet the evolving needs of modern production lines, where precision, speed control, and operational stability are essential.

Its high-responsiveness vector algorithms ensure smooth acceleration and deceleration, even under fluctuating loads.

This makes the inverter particularly effective in packaging systems, synchronized conveyors, multi-axis applications, and automated feeding units where timing accuracy directly impacts production quality.

In addition to its robust motor control capabilities, the 3G3M1-A2004-ECT supports advanced diagnostics, allowing maintenance teams to detect abnormalities before they escalate into failures.

Real-time monitoring over EtherCAT enhances data visibility, enabling predictive maintenance strategies that significantly reduce unplanned downtime.

Its compatibility with Omron’s Sysmac ecosystem further strengthens integration, ensuring centralized control and simplified network configuration.

The inverter’s compact footprint is ideal for high-density control cabinets, especially in facilities aiming to optimize panel space without compromising performance.

Its energy-efficient operation contributes to long-term cost savings while supporting sustainability initiatives.

When combined with its safety certifications and rugged IP20 construction, the 3G3M1-A2004-ECT stands out as a reliable, future-proof solution for industries seeking improved productivity, reduced energy consumption, and superior motion control.